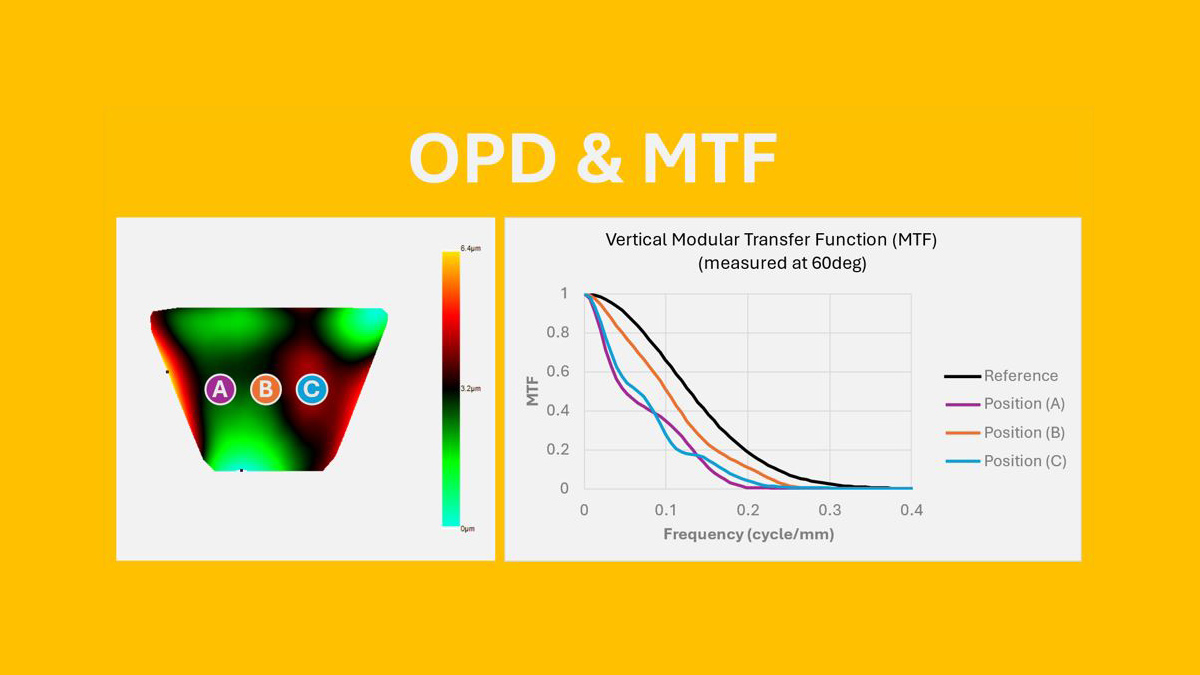

This virtualized camera zone can then be tested in our simulated optical lab enabling us to analyze various metrics, including optical power, double image, wavefront, and the increasingly popular modulation transfer function (MTF). Through advanced ray tracing, image processing, and vector calculus, our system achieves high-precision instrument equivalence. These tests can be conducted on a windshield sample in a lab setup or applied to every unit in a production line for 100% in-line measurement accuracy. Once captured, the data from our virtualization system offers valuable insights into ADAS optical pipelines early in the design process. This approach optimizes initial sample evaluations for glassmakers before presentation, empowering OEMs with critical insights. It helps them to balance complex ADAS manufacturer requirements with real-world production challenges—achieving cost-effective, high-quality outcomes.

Revolutionizing Camera Zone Inspection

For several years, Synergx has been at the forefront of optical measurement systems for automotive glass, offering solutions that can be seamlessly integrated in-line on production lines or used in lab environments. Our latest system virtualizes the glass surfaces (surfaces 1 and 4) in the camera zone using polynomial splines that are C1C^1C1-continuous. This ensures a smooth mathematical representation with a continuous normal vector on both sides of the glass, enhancing measurement accuracy.